Understanding Large Scale HVAC Systems and Innovative Cooling Solutions

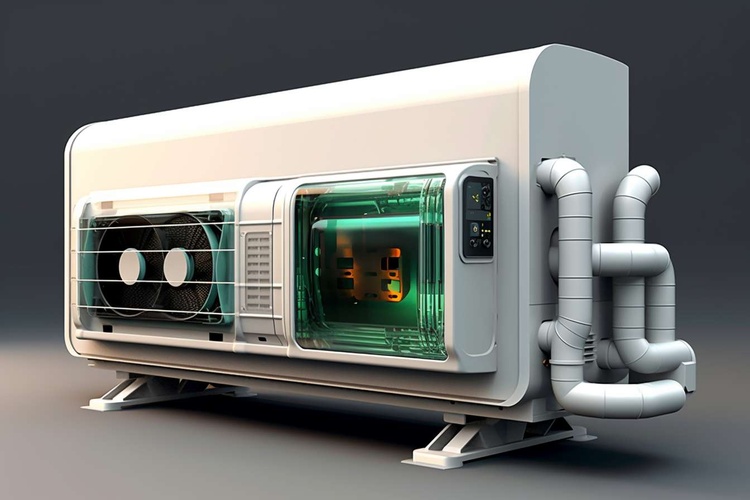

Air conditioning technology has evolved dramatically over recent decades, shifting from simple comfort systems to sophisticated climate control solutions that integrate with building management systems and environmental controls. Large scale HVAC systems now power everything from massive data centers to sprawling commercial complexes, utilizing advanced technology to balance energy efficiency, performance, and sustainability. These modern systems represent a significant departure from traditional cooling approaches, incorporating smart controls, high-efficiency components, and alternative cooling methods to meet increasingly demanding requirements.

How Are Large Scale HVAC Systems Designed for Commercial Applications?

Large scale HVAC systems require specialized engineering considerations that differ substantially from residential applications. These systems must maintain consistent temperatures across vast spaces while accounting for varying occupancy levels, heat-generating equipment, and specific zone requirements. Modern commercial HVAC designs typically incorporate multiple air handling units, chillers, cooling towers, and extensive ductwork networks that work in concert to deliver precise climate control.

The scale of these systems introduces unique challenges, including the need for redundancy to prevent catastrophic failures, sectional control capabilities for energy conservation, and sophisticated monitoring systems that can identify performance issues before they escalate. Engineers must also account for future expansion requirements, seasonal operational variations, and the integration of renewable energy sources to maximize efficiency and minimize environmental impact.

What Makes Modern Cooling Solutions Innovative?

Innovation in cooling technology has accelerated dramatically in recent years, driven by the dual pressures of rising energy costs and increasing environmental concerns. Several breakthrough technologies are reshaping how large buildings and facilities approach climate control:

Variable refrigerant flow (VRF) systems represent one of the most significant innovations, allowing for simultaneous heating and cooling in different zones while recovering waste heat. Magnetic bearing chillers eliminate traditional mechanical friction points, dramatically reducing energy consumption and maintenance requirements. Thermal energy storage systems shift cooling load to off-peak hours, reducing demand charges and improving grid stability.

Perhaps most promising are advances in evaporative cooling technology that combine traditional approaches with modern materials and controls, delivering substantial energy savings in appropriate climates. These innovations are complemented by developments in natural refrigerants that offer comparable performance to traditional chemicals without the associated environmental hazards.

How Do High-pressure Air Compressors Function in Modern AC Systems?

High-pressure air compressors play a critical role in many large-scale cooling applications, particularly in systems utilizing centrifugal chillers and certain specialized industrial cooling processes. These compressors create the pressure differential necessary to circulate refrigerant through the system, effectively transferring heat from inside to outside the conditioned space.

In modern systems, high-pressure compressors have evolved significantly. Oil-free centrifugal compressors utilize magnetic bearings that eliminate mechanical friction, reducing energy consumption by up to 40% compared to traditional designs. Variable speed drives allow these compressors to modulate their output precisely based on cooling demand, avoiding the energy waste associated with traditional cycling operation.

The integration of advanced monitoring capabilities enables predictive maintenance, with sensors tracking vibration patterns, temperature fluctuations, and power consumption to identify potential failures before they occur. This capability is particularly valuable in mission-critical applications like data centers, where cooling system reliability directly impacts business operations.

What Role Does Smart Technology Play in Cooling System Management?

Smart technology has revolutionized how cooling systems operate, moving beyond simple thermostatic control to comprehensive building management integration. Modern systems incorporate multiple layers of intelligence, from equipment-level controllers that optimize individual component performance to building automation systems that coordinate all aspects of environmental control.

Advanced analytics platforms now process data from hundreds or thousands of sensors throughout a facility, identifying inefficiencies and automatically adjusting system parameters to optimize energy usage while maintaining comfort conditions. Machine learning algorithms analyze historical performance data alongside weather forecasts and occupancy patterns to predict cooling demands and preemptively adjust system operations.

The emergence of cloud-based monitoring and management platforms allows facility teams to track performance metrics, receive automated alerts, and even implement remote system adjustments. This capability proves particularly valuable for organizations managing multiple facilities across different geographic regions, enabling centralized expertise to be applied across the entire portfolio.

How Are Energy Efficiency and Sustainability Addressed in Contemporary Cooling?

Energy efficiency has become the defining focus of modern cooling system design, driven by both economic and environmental imperatives. Today’s most advanced systems incorporate multiple efficiency-enhancing technologies, including heat recovery systems that capture and repurpose waste heat, economizers that leverage favorable outdoor conditions for “free cooling,” and advanced control algorithms that continuously optimize system performance.

Thermal storage solutions offer another efficiency pathway, using off-peak electricity to produce ice or chilled water that provides cooling capacity during peak demand periods. This approach not only reduces operating costs but also helps utilities manage grid loads more effectively, potentially avoiding the need for additional power generation capacity.

The sustainability focus extends beyond energy consumption to refrigerant selection, with the industry transitioning to solutions with lower global warming potential. Natural refrigerants like ammonia, CO2, and hydrocarbons are seeing increased adoption in appropriate applications, while next-generation synthetic refrigerants offer improved environmental performance compared to their predecessors.

What Considerations Apply to System Sizing and Implementation?

Proper sizing of large-scale HVAC systems requires balancing immediate needs against future requirements while avoiding the inefficiency associated with oversized equipment. Modern design approaches utilize sophisticated modeling tools that simulate building performance under various conditions, enabling engineers to optimize system capacity and configuration.

Implementation challenges include coordinating installation around existing operations, managing the physical space requirements of large equipment, and ensuring that control systems properly integrate with building management platforms. Commissioning processes have grown increasingly rigorous, with extended testing periods and detailed performance verification before system acceptance.

The total cost of ownership perspective has gained prominence in system selection, with initial equipment cost representing only a fraction of lifetime expenses. Energy consumption typically accounts for 60-80% of lifetime costs, while maintenance requirements, reliability factors, and expected service life also significantly impact the financial equation.

Conclusion

Large scale HVAC systems continue to evolve rapidly, with innovations in compressor technology, smart controls, and energy efficiency strategies reshaping industry practices. As sustainability concerns intensify and energy costs rise, the emphasis on optimized system design and operation will only increase. Organizations that understand these technologies and implement appropriate solutions stand to benefit from improved comfort conditions, reduced operating costs, and enhanced environmental performance.